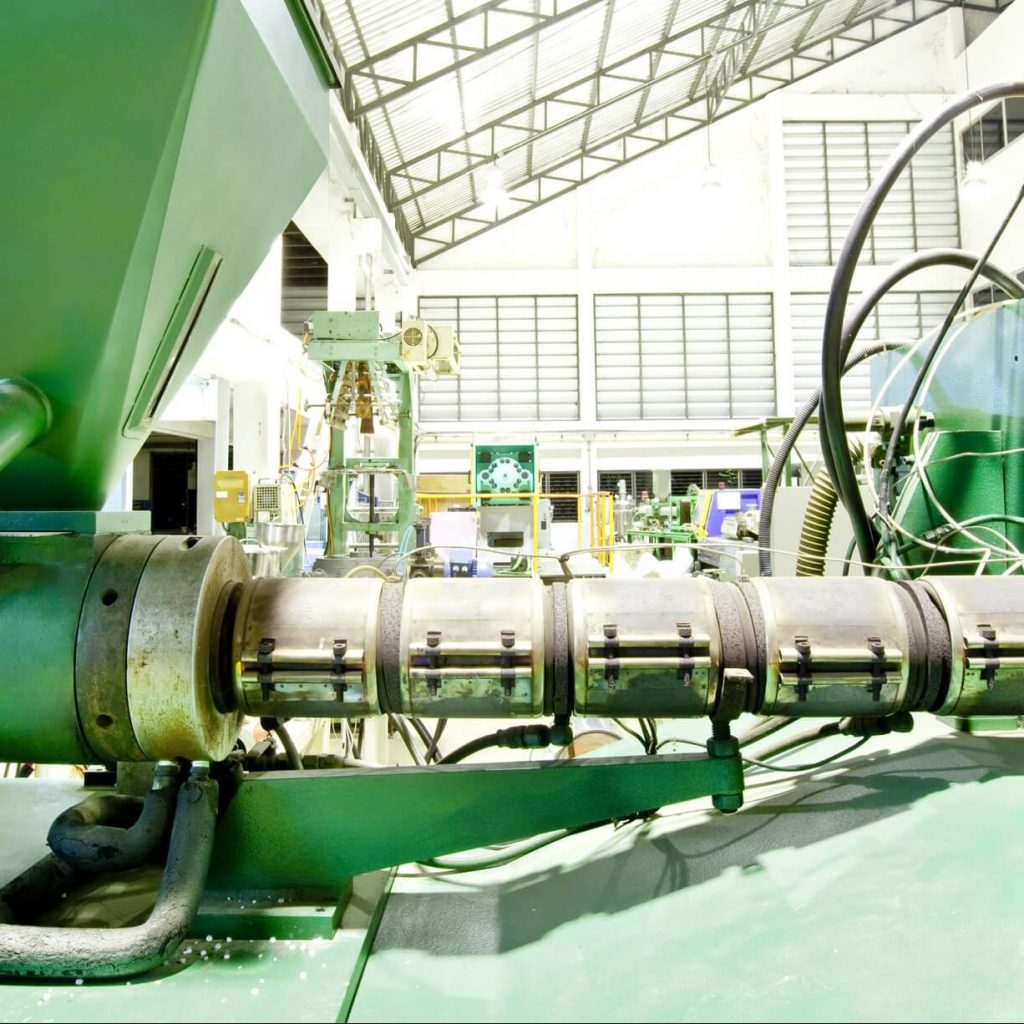

Power Pack Repair

Hydraulic Power Pack (Hydraulic power unit HPU) Repair

Apex Hydraulics is at the forefront in the repair and servicing of a wide range of hydraulic power packs.

Saving money is vital to any business so it is important that you regularly maintain your power packs. The alternative could be damaged equipment which impacts on your company’s productivity and could lead to costly downtime. So make sure your equipment is regularly serviced by one of our skilled engineers.

And, if you can’t bring your part to our workshop, we’ll come to you with our team of skilled on-site engineers.

A quality service every time:

- The Apex team has the experience and capability not only to repair your unit but also to provide recommendations to improve design and efficiency

- Apex has worked with all the major component manufacturers and has access to the complete range of spare parts

- Our site engineers will work with you during your shut down periods to provide full servicing and testing

So down time due to hydraulic ram failure could be a thing of the past!

Free Strip and Quote Service

In addition, we offer our FREE ‘Strip and Quote Service’ which includes;

- a complete strip down of your power pack;

- a comprehensive assessment and full diagnosis;

- sourcing of all spares required to complete the repair;

- providing you with a fully itemised quotation before any work commences.

Frequently Asked Questions

We can repair any sized power pack. We offer a free strip and quote service, where the power pack is brought into our workshop and stripped, so our experienced hydraulic engineers can assess the power pack for any wear or issues, before giving you a detailed diagnosis and an accurate quote. For power packs too large or too difficult to be brought to Apex, we offer an on-site maintenance and repair service.

Our turnaround time depends on the project. A standard service often only takes a couple of days; including filter changes, oil changes and function testing. We understand that most companies need as little down time as possible, so wherever we are able we will work alongside your company to ensure that we service your power pack during shut down periods.

Dirty oil can build up, damaging seals and valves, causing breakdown of the entire hydraulic system. Regular services ensures that oil remains clean and that any parts that are becoming worn can be replaced, preserving the lifespan of your equipment and avoiding the downtime of machinery breakdowns.

In most cases, we would recommend a service every 12 months as a starting point. If oil remains clean and components in good repair across several services, it may be possible to extend the time between services. Our Bypass Filter Units can help to extend the time between services by keeping oil clean and protecting components from wear and contamination, keeping the system running efficiently.

Apex has years of experience of working with power packs. Our specialist engineers will assess and diagnose the issues, issuing a free quote. We and are not bound by a reliance on one particular manufacturer – meaning that we will always source the optimum part available for your power pack. All work is stringently tested by our in-house test facility. We are able to test the power pack at any pressure required and you can request printed copies of test results for your own records.

We are confident that we would be able to repair any damage to any power pack. However, there may be some occasions when it is more financially efficient to replace the power pack with a new one. In this case we can provide a power pack that is tailored to suit your exacting requirements.

Our engineers can suggest a number of ways in which your power pack can be modified to be more efficient. This may mean changing parts or installing filter unit rigs, but can mean fewer repairs across the lifespan of your hydraulic system.

What we do

- Conduct a full assessment of the equipment

- Decide the best possible course of action

- Assess how many parts can be salvaged and

- Decide if it is cost effective for us to repair

Related Case Studies for Power Pack Repair

Read more about our experience with power pack repair within the case studies below

Related Sector Experience for Power Pack Repair

Read more about our sector experience associated with power pack repair

Latest News

Read more about our latest news below