A Day in the Life of… A Design and Project Engineer

Steven North

Steven North joined Apex 12 years ago as an apprentice. During his apprenticeship, Apex encouraged him to gain engineering and design qualifications at a local college. Throughout his apprenticeship he worked in the Apex Strip and Assessment department, the Machine Shop, Ram Assembly, the Stores department (buying in consumables), the Inspection department and Painting workshop. His years of assisting in the different departments have given him invaluable experience when it comes to designing practical solutions for the client’s needs. Having gained his engineering qualifications, he has been a design and project engineer with Apex for the past 9 years.

Steven’s role means that he sees projects through in their entirety; from initial meetings, to quoting a project, designing it, certifying it, then going on site to check it as it is put in situ. This means that his day can be unpredictable but is always interesting.

The best thing about working at Apex is the diversity and variety of the work.

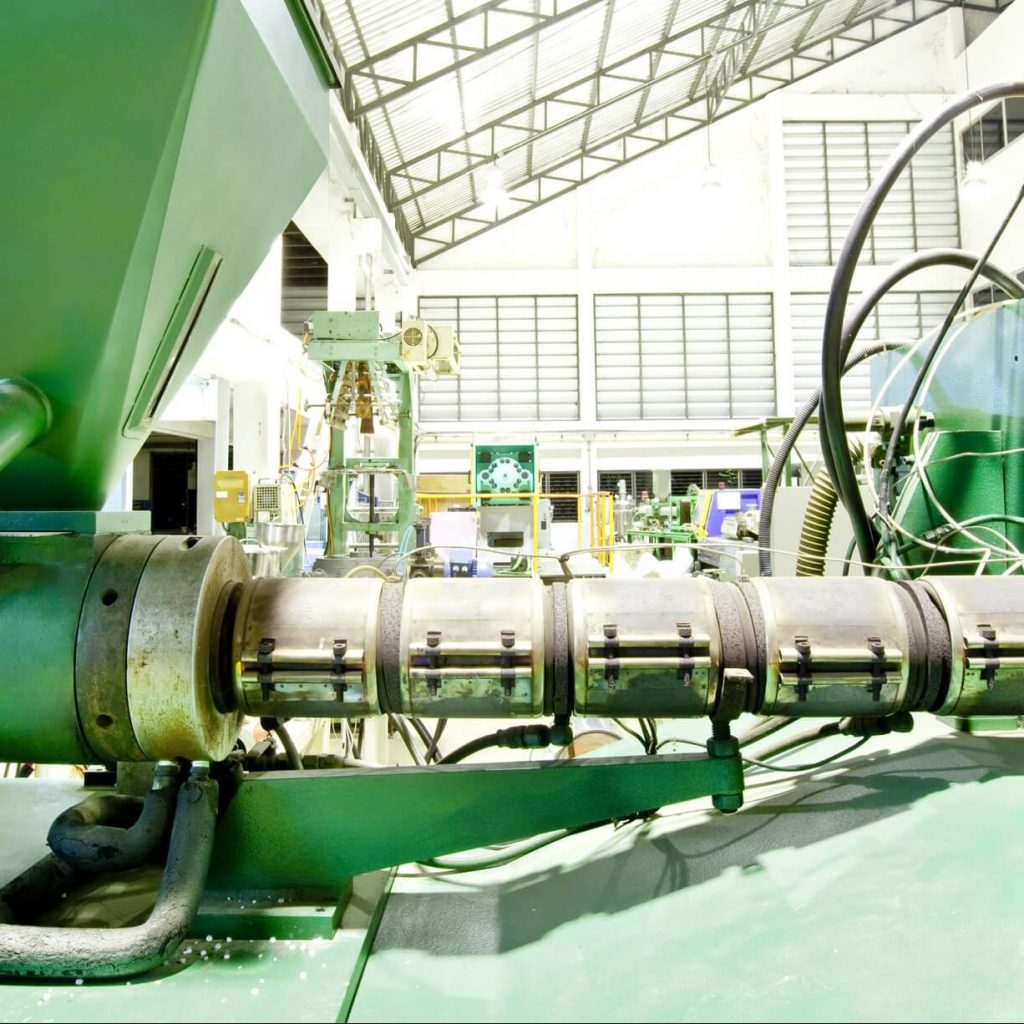

A typical offshore cylinder project will require a quotation and meeting with the clients before the design stage. In most cases the client will know what they want in terms of specifics such as the length and the weight that it needs to be able to pull. Apex can design a cylinder that meets those requirements. Stephen and the design team make in depth calculations, do drawings and send this to the customer for approval. For offshore work, independent surveyors need to witness the welding and testing of all the equipment and rubber stamp it to say it’s all correct and approved. This is necessary for oil rigs in order to be able to get insurance. Every single item that goes into the rig is individually surveyed.

When it comes to the actual design work, Steven works on several different computer programs. The designs vary hugely depending on the task. He designs in 2D Autocad, 3D Solidworks and 3D Inventor. Everything Apex design is bespoke, though some systems are more complex than others. There may be space restrictions, different steels for different environments, or different seals being required. In some cases, the fabrication will already be built, so the design team will need to fit the hydraulic system into a piece of equipment that is already in situ. This means that they have to be careful to ensure that the cylinder fits into the fabrication, while also being strong enough to do the job that it is required to do.

On occasion a customer may have a stipulation regarding what the machinery needs to do, but not have any current fabrication. At this point, Apex needs to work together with the machine manufacturer to design the hydraulic system from scratch.

Often, rather than building a new hydraulic system, the design team will be asked to design repairs to an existing system. Sometimes the hydraulics will be sent to Apex for Strip and Assessment, but on other occasions the client may want to keep their machinery running. Some equipment problems may not be serious enough to require immediate closure and in these instances they can continue to work for several weeks while new hydraulics are prepared. This is likely to require Steven going on location and measuring up on site, quoting for repairs for a new hydraulic system, designing the new hydraulics and overseeing the new build. At the very least, he will need to design new internals as without stripping the old hydraulics it is impossible to know exactly what has gone wrong inside. In some cases the best course of action may be a complete redesign, but within the parameters stipulated by the current fabrication.

An additional area of work for Steven is to check on equipment that he designed months before, which are currently being fitted and inspected. If there are issues Steven may even need to go off shore. Last year he flew out to Germany to go onto an offshore vessel to fault find hydraulic issues. With such a varied role, there is no such thing as a “typical” day for a design and project engineer, but Steven enjoys the diversity of the job and the varied challenges that each day brings!

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…