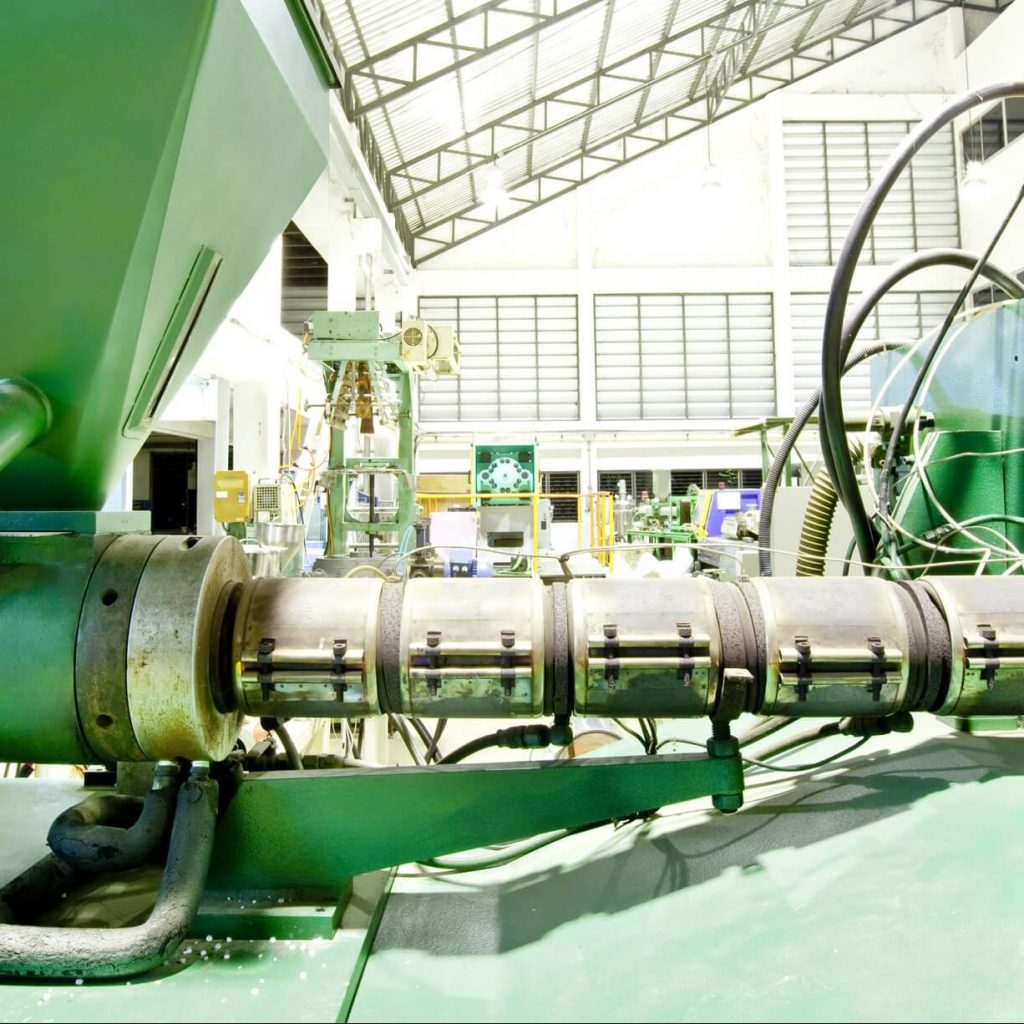

Valve Repair

Valve Repair

As one of the UK’s leading valve repair experts, we pride ourselves on providing you with a speedy, efficient, unrivalled quality of service – every step of the way.

Apex Hydraulics FREE Strip and Quote Service

Apex Hydraulics offers you our FREE ‘Strip and Quote Service’ which includes:

- a complete strip down of your valve;

- a comprehensive assessment and full diagnosis;

- a speedy assessment to reduce critical downtime

- sourcing of all spares required to complete the repair;

- providing you with a fully itemised quotation before any work commences.

Our extensive experience working with all the major manufacturers means we have an unmatched knowledge of the majority of valves. And, allows us to have immediate access to spare parts should they be needed.

Our extensive experience working with all the major manufacturers means we have an unmatched knowledge of the majority of valves.

Our expert in-house technical team is always on hand to provide you with professional support. So should you need to discuss your concerns, please call us on +44(0)1924 456788 and we’ll do our very best to help you.

And finally, don’t worry if you have an obsolete valve, our in-house machine facility will take care of it.

Here is a selection of the types of valves we repair:

|

|

We are yet to find a valve we cannot fix!

Here is a selection of just some of the manufacturers we have worked with over the last 30 years:-

|

Frequently Asked Questions

Apex have decades of experience of repairing all parts of hydraulic cylinders, including valves. We work across a huge number of different industries and applications so are well versed with requirements for different systems, including corrosive environments, hydraulic systems with high cycle rates and systems working under extremely high and low pressures. We have a state of the art workshop in Dewsbury, where we employ design engineers and expert technicians with a vast experience of working with valve repairs – including obsolete valves.

Yes, we have experience of repairing valves that are obsolete and no longer manufactured. Where parts are no longer available, we can engineer news part ourselves, in our Dewsbury workshop. In cases where repair is not financially viable, we work with a large range of different manufacturers, so are always able to find a new valve to replace a damaged one when necessary.

While our hydraulic valve repairs do often have the effect of making them more durable, trying to improve on a working hydraulic valve to make it more robust is not economically viable for our clients. It is far more financially efficient for us to find an alternative valve that is more durable.

In most cases we will need the valve at our workshop in Dewsbury, where it can be assessed by our strip and assessment team and a good repair can be designed and carried out with our state of the art machinery.

We match the materials used in the original valves, only changing where we can make them more durable using a different material. Valves are usually made of carbon steel, but sometimes stainless steel is used, particularly if the valve is subject to a corrosive environment. We also apply special coatings where required.

We have a department dedicated to inspecting and testing our hydraulic systems. All repaired or manufactured parts are tested stringently, ensuring there are no imperfections. We can test to any pressure required by our clients and are also happy for third party verification or clients to view the testing.

Yes, we can perform testing on your valve under any pressure required by you, in order to produce a Certificate of Conformity.

We understand the time constraints on our clients, so where possible, we try to repair parts within 5 working days. With good relationships with all our suppliers, we are usually able to source new parts within 24 hours and our machine shop is able to quickly engineer new parts where required.

Proud of our Quality Status

Our ISO 9001:2015 certification means we can focus on providing our customers with unbeatable technical expertise.

Certification available with each task completed

Full ‘test and certificates of conformity’ are available should you need them.

Full ‘test and certificates of conformity’ are available should you need them.

Some valves we see are now obsolete and therefore it can be difficult to purchase spares. However, with our qualified design team and machine workshop, we can engineer the parts required for your job.

Related Case Studies for Valves

Read more about our experience with valves within the case studies below

Related Sector Experience for valves

Read more about our sector experience associated with valves

Latest News

Read more about our latest news below