Valves

We stock the best.

Our Experience with Valves

Valves are an integral part of any hydraulic system and although Apex do not manufacture valves, we do stock quality, brand name valves from manufactures such as Integrated Hydraulics, Parker, Vickers, Eaton, Hauhinco, Commercial Hydraulics, Bosch Rexroth and many others.

For more information on the selection available go to our brand manufactures page.

Our Products Include:

|

|

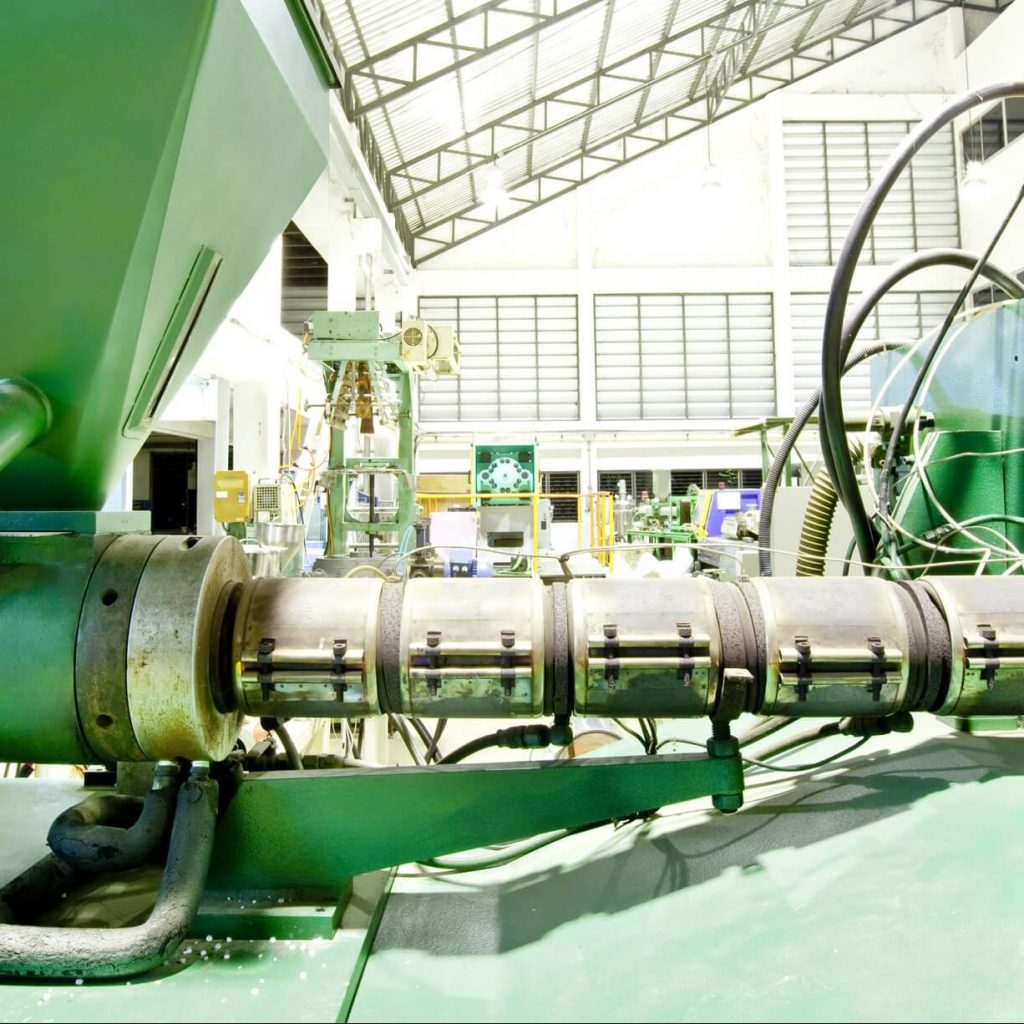

Hydraulic screw-in cartridge valves offer benefits as well as savings.

Frequently Asked Questions

Apex has decades of experience at choosing valves for bespoke hydraulic cylinders – so we know what materials, makes, models and coatings will be suitable depending on the environment and application of your cylinders.

At Apex we do not manufacture our own hydraulic valves, but we choose from a wide selection of manufacturers; meaning that we can pick and choose the best for our bespoke cylinders, rather than being tied to one make. We may even use multiple manufacturers within one system, to ensure that each valve is optimum for each use.

Screw in technology allows for quick, seamless repair and replacement in the event of any faults. It consists of one manifold block with a number of screw in cartridges, each valve having its own function. This allows for complex hydraulic systems to be contained within one neat self-contained block.

Apex is extremely experienced at choosing valves according to the application – contact us today for advice.

There are three main categories of valves within hydraulic systems, each designed to perform a specific task. Flow control valves open gradually, to limit the amount of oil that comes through at a time. Directional control valves control the direction of the flow of hydraulic fluid, as well as the starting and stopping of the flow. Pressure control valves are set to open and close at certain pressures.

Within these three categories, there are a huge number of types of valves. Proportional valves open gradually, to limit the amount of oil that comes through at a time, while standard valves are just either open or closed. Over-centre valves control the decent of the extension of the cylinder rod as it passes the central pivot point, stopping the rod from suddenly extending extremely quickly when it passes the tipping point.

Within all the different valve types are large numbers of materials and designs, offering an almost unlimited choice. Apex have years of experience of choosing the right valve for each part of your bespoke hydraulic system.

While valves are often placed with the power unit or control panel, they can also be mounted directly onto the cylinder. This can be a safety feature, removing the risk of the cylinder failing in the event of a hose burst. Putting the valves closer to the location they are serving can be a useful design feature under certain circumstances due to this minimisation of the risk of failure.

There is a huge range of different materials and coatings. Typically valves can be just any carbon steel. However, there are also many situations where stainless steel may be required, such as in corrosive environments or when water based fluids are being used for environmental reasons, or to avoid risks of combustion, such as in forges or mines. Sometimes valves will also have special coatings, for additional lubrication or corrosion resistance.

Yes, we can repair or find a suitable replacement for a wide range of valves, including obsolete or unknown valves.

Screw-in cartridge valve technology enables us to concentration of any number of hydraulic control functions into a single block, whether it is a single valve dictating the descent of a cylinder or an elaborate manifold (Hydraulic Integrated Circuit) controlling all the operations of a machine, benefiting the machine builder with improvements in performance and reduction in costs.

By exploiting cartridge valve technology systems will require fewer pipe work connections eliminating potential leak paths and so the possible environmental impact of a machine and reducing the systems pressure losses. In service, productivity improvements and cost savings can be achieved as maintenance and fault diagnosis can be considerably eased and if a cartridge does need to be replaced it can be done simply and quickly.

We can design and manufacture any size block to perform as many different functions as the user requires. Use our contact page to find out more.

Related Case Studies for Valves

Read more about our experience with valves within the case studies below

Related Sector Experience for valves

Read more about our sector experience associated with valves

Latest News

Read more about our latest news below