Factors to Consider when Making a Maintenance Plan

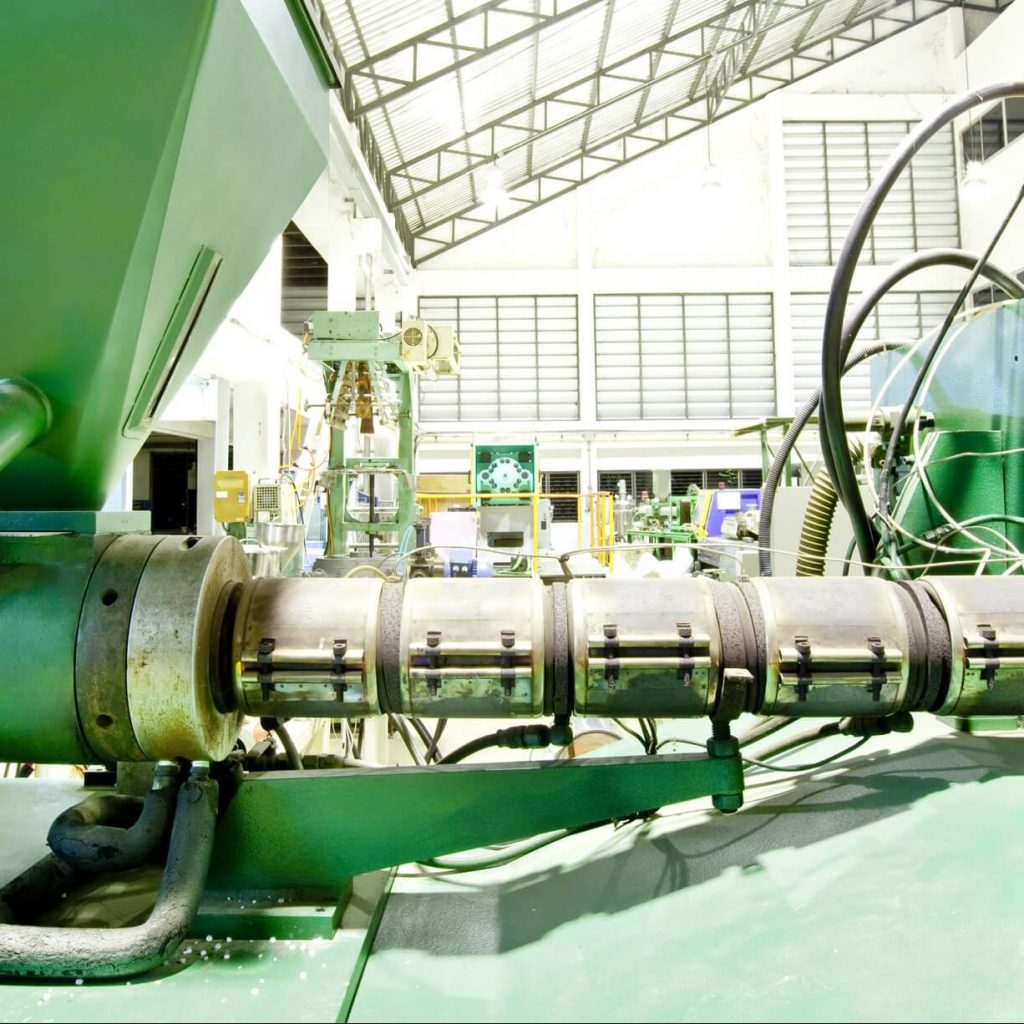

Hydraulics are complex pieces of equipment. Maintaining them is vital, for a number of reasons. The location of the equipment, (particularly the cleanliness, or otherwise, of the location), the frequency of the equipment’s use and the qualifications and experience of your staff will all have a direct bearing on the maintenance plan that you choose.

Here are some aspects of hydraulic equipment maintenance that you will need to consider.

Keep Your Hydraulic Equipment Clean

It is easy for particles of dirt to enter your hydraulic equipment system; both through routine use and through basic errors. The financial effects of dirt in the system can be extremely significant, as well as there being potential safety repercussions when the dirt particles cause the equipment to malfunction.

Particles of dirt in your hydraulic equipment will vastly reduce the life of it’s parts. An over-clogged filter can cause massive damage by releasing a collection of dirt all at once. Dirt can also cause valves to stick, necessitating expert servicing, and causing down time.

New components arrive from the manufacturers carefully packaged, having been produced in a perfectly clean environment. Ensure that these parts are only removed from their clean storage at the last possible moment before being fitted.

Ensure that any wiper seals or external rubber bellows around the cylinder are kept in good condition, so that they continue to keep any particles of dirt from entering the system with the cylinder rod.

Check Filters

As mentioned above, filters are hugely important in keeping your hydraulics running smoothly. For a properly trained individual, they are relatively easy to check, clean and change. Well maintained filters provide financial savings by extending the life of your equipment.

Oil Maintenance

Oil in hydraulic systems does not need to be a consumable resource. However, if the oil is allowed to become dirty it will need to be changed, at expense; or else it will contaminate all the parts of your hydraulic system, potentially causing the system to fail and resulting in down-time that could easily have been avoided.

Creating a good oil maintenance plan, carried out by experts, will be a great financial investment, avoiding spiralling costs of downtime and repairs caused by a build up of unclean oil.

Check For Faults

Make sure that the users of your hydraulic equipment are trained to look out for warning signs that equipment may be developing faults. This way, experts can be called in before breakdowns occur.

Create a Maintenance Log

There are many maintenance planning computer programmes available that can be utilised to schedule different types of maintenance for different parts, over different shifts – as well as the regular services by experts. Ensure that all your staff keep to the program and complete a log so that other staff members are always aware of what has been done and what is still to do. It is a good idea to work through your own maintenance plan with qualified hydraulic equipment engineers.

Schedule Regular Services By Experts

Some elements of your hydraulic equipment will need to be checked and repaired by qualified hydraulic equipment engineers, with specialist equipment. A bit of planning at this stage can reduce down time massively, by ensuring that all specialised maintenance is done at the same time (where possible). Apex offer a Hydraulic Pump Test Rig, which can test your pumps while they are closed down for scheduled maintenance. Our expert technical team measures, collates and analyses the pump’s data and once any repairs have been made, we provide you with a full graphical analysis of the testing.

[1] Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 201.

[2] Darbyshire, A. 2008. Mechanical Engineering. Oxford. Elsevier Newnes, 373.

[3] Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 201.

[4] Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 123-124.

[5] Winston, M. 2012. Essential Hydraulics, Fluid Power, Basic. Self Published, 103.

[6] Parr, A.1991. Hydraulics and Pneumatics. Oxford: B H Newnes, 213.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…