Can Double Acting Telescopic Cylinders Make Offshore Work More Efficient?

What is a Double Acting Telescopic Cylinder?

Whilst most cylinders only have a single stage, a telescopic cylinder can have multiple stages. Though this is not a new phenomenon (it is often used, for example, on tipping trucks), there are a couple of issues with standard telescopic cylinders.

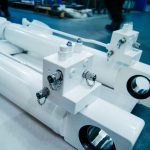

Firstly, they require gravity to push the stages back into the retract position – which is not possible for horizontal equipment. Apex has produced a telescopic cylinder that can retract as well as advance, using a series of internal hydraulic fluid feed pipes, increasing the variety of uses for the design.

The second issue with standard telescopic cylinders is that the stages do not advance and retract at a constant speed. This can have safety implications when personnel are working closely with heavy equipment as sudden movements could potentially cause accidents. In safety critical applications, the double acting telescopic cylinder can be designed to work at a constant speed; often referred to as a synchronized telescopic cylinder.

Why is this significant for the offshore industry?

Working offshore or subsea, means that there are often significant challenges resulting from the depths and distances involved. Telescopic cylinders can be adapted for a number of different applications. Being able to lift a piece of equipment in half the amount of time means significant savings of time and money; allowing the company to proceed with new projects more quickly. On occasions where there are space limitations there are obvious advantages in a hydraulic cylinder that can extend to multiple times the distance of a standard cylinder, but within the same space.

Possible Offshore Uses for Double Acting Telescopic Cylinders

- Lifting devices – As detailed earlier, any fabrication lifting risers, pipes, oil rig structures or other materials out of the sea will benefit from machinery that can lift a multiple distance per stroke, with more efficient use of space.

- Extending platforms – dual acting telescopic cylinders are a particularly useful addition to access platforms. The cylinder can extend to an extremely large reach, sending personnel or machinery longer distances from the body of the equipment. The dual action allows the rod to retract as normal despite the horizontal mounting.

- Jack up rigs: Machinery used to place drill rigs into accurate positions may benefit from double acting telescopic cylinders. A jack up rig will lift itself out of the water using four “legs” and then with another four legs it repositions itself on the sea bed. Telescopic hydraulic cylinders decrease the time taken to lift and lower the rig in and out of the sea.

The future may see more use of double acting telescopic cylinders within the offshore and subsea industries, as energy companies look to become increasingly efficient. For more information about their bespoke cylinder design services, contact Apex Hydraulics.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…