Inspiring the Next Generation of Hydraulic Engineers

Apex hydraulics benefit from the employment of a number of highly experienced hydraulic engineers.

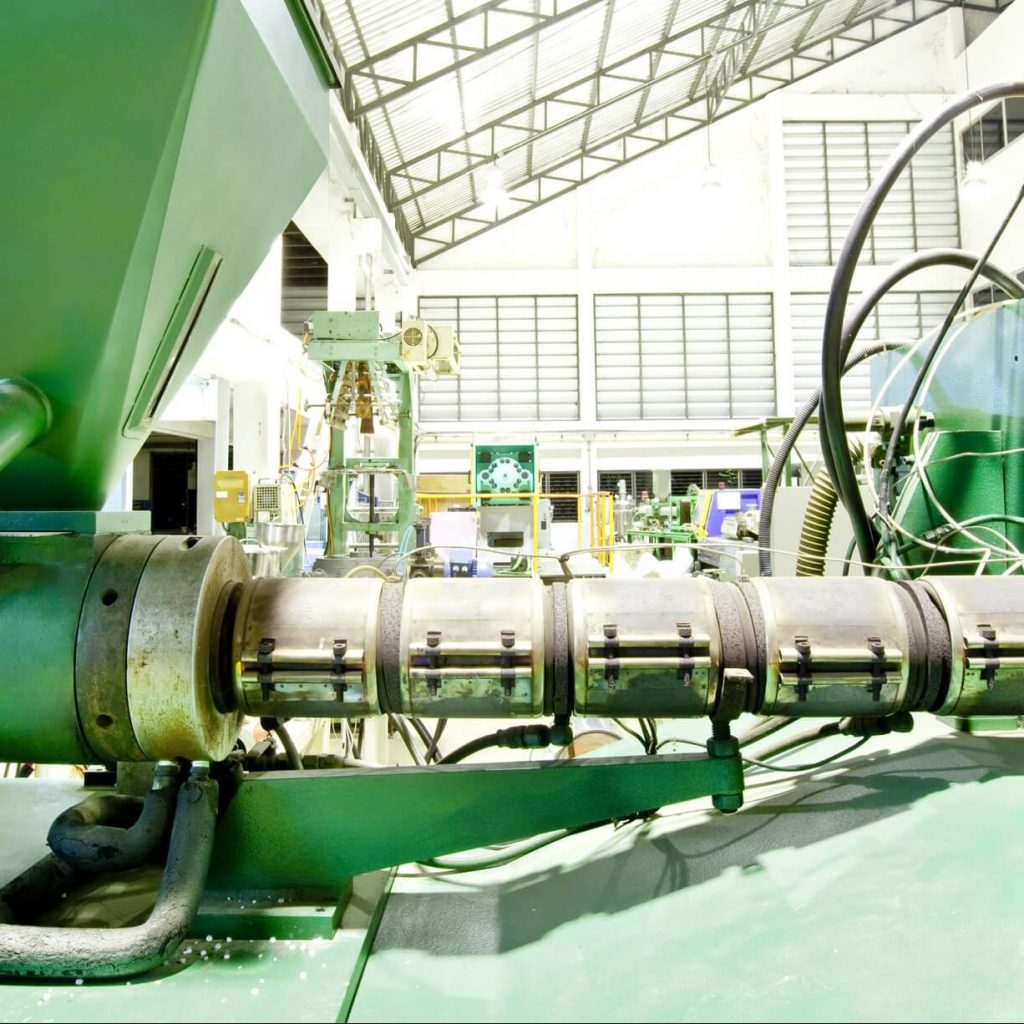

Apex hydraulics benefit from the employment of a number of highly experienced hydraulic engineers. Many of our foremen have been working in the industry for decades and have accumulated a wealth of experience – initially by working within the mining industry which was the core of Apex’s clientele several decades ago. The extremely robust machinery required for the harsh mining environments paved the way for the skills required to meet the high standards required by the industries we currently work with, including offshore work, recycling, rail and plastic injection moulding. Some of our highly experienced engineers are now considering their retirement and it is vital that the next generation of well-trained engineers are cultivated to take their place.

Harry McGowan, Age 25.

Harry works in the machine shop, using a multitude of machines. This machinery comprises of manual and Computer Numerical Control (CNC), turning lathes and milling machines, all of which are used in both the production and repair of hydraulic cylinders and their associated components. He started working for Apex hydraulics through an apprenticeship.

Why an apprenticeship?

Harry has always wanted to work in engineering, but having started a University course in Chemical Engineering, he found that the course was not particularly beneficial to him and instead started applying for jobs through city training services.

While at Apex, Harry has had the opportunity to benefit from a wide variety of training. Initially he received induction training, which taught a wide variety of topics at basic level. He worked on crane and forklift courses and did training alongside any new machinery that he was asked to work on. The apprenticeship scheme that he is working with is also providing him with an NVQ level 2 and 3 in mechanical engineering. A trainer comes to Apex and works through a series of topics including Health and Safety and working practice.

The third part of the training scheme comprises of a BTec, carried out one day a week at a local college. This will give Harry a BTec Level three in mechanical engineering. Harry says;

“There is 100% more learning in a workplace experience than through a University course. You can’t put a price on that. A lot of Uni places have started doing a year in industry, as there is no work place skill taught in the course.”

What does the work entail?

Harry works under machine shop foreman Ian Washington and workshop manager Richard Greaves. Both have several decades of experience in the hydraulic engineering industry. They support the apprentices in every way possible.

“If there’s ever a problem we only have to ask; they are always there to support us.”

He finds that the training and the workplace complement one another, with the academic studies supporting his workplace experience, and the workplace being a very positive influence on his studies. The apprenticeship is very broad, covering a wide range of practical engineering skills, with the BTec informing a lot of the theoretical and technical detail. The apprenticeship is narrowed down with relevant modules specific to the production of hydraulic cylinders. Meanwhile, the warehouse foremen continually share their experience, offering on-the-job training that could not be found in an exclusively lecture based training scheme.

What do you like best about Apex Hydraulics?

Harry’s favourite aspect of work at Apex is the challenge, and the varied and ambitious jobs that we take on. He says;

“We’ll take on anything at Apex – it’s a challenge to gets things done. It makes you strive to work harder and push things through.”

Where do you see yourself in ten years time?

“I’d like to see myself progress through the company. I’ve spoken to the directors about possibly taking a managerial role or going to work in the design office. I just want to be as successful as I can possibly be.”

Apex are delighted to be able to support future hydraulic engineers and designers, such as Harry, as they study, train and progress, working alongside our experienced management and foremen.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…