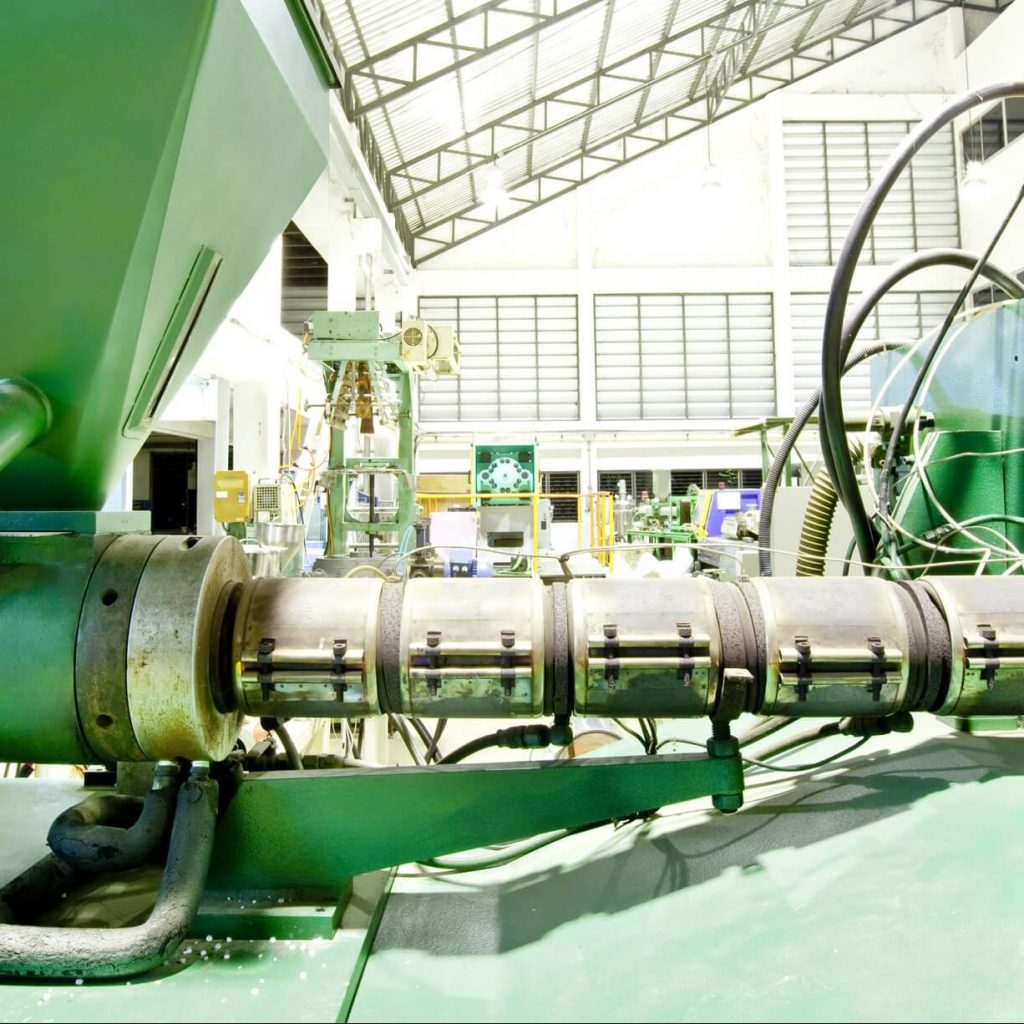

Hydraulic Systems

Four Offshore Challenges

There are few situations more challenging for hydraulic cylinders than the ocean environment of the offshore industry. It is vital that all equipment is strong and hard wearing and there are huge obstacles in terms of ensuring that machinery does not corrode, that it can be worked remotely, that it is exceptionally reliable and highly robust. Hydraulic cylinder specialists – Apex hydraulics – have invested time and skill into designing bespoke hydraulic cylinder solutions, utilising the latest technology to ensure outstanding results for hydraulics based within the offshore industry.

Remote Locations

Many offshore rigs are hundreds of kilometres from the shore and difficult to access, particularly in extreme weather conditions. Depending on the application, some hydraulics are then taken hundreds of metres below the surface of the water. There is no opportunity to return faulty items to the factory for adjustment! All machinery must work perfectly, first time. Apex has a state of the art test facility with an independent Inspection department testing every part rigorously to ensure each aspect is perfect. In addition, they facilitate regular inspections by third party inspectors; required for insurance purposes and adding an additional level of confirmation that all parts are completely faultless. Apex has experience of working together with offshore facilities based world wide- we have parts working hundreds of metres under the sea, hundreds of kilometres from the shore, thousands of kilometres from our base in Dewsbury, England!

Salt and Corrosion

The salt from ocean spray can very easily corrodes parts that are used on the surface of rigs and ships, as well as causing pitting and scratches which can lead to seal failure, oil contamination and eventually machinery failure. This is a significant issue for expensive parts that are not easily repairable and replaceable. Together with industry experts, Apex has developed Corex; a piston rod coating with extreme hardness of up to 1400 Hv, meaning that it has an outstanding resistance to corrosion and impact. Bond strength is up to double that of standard Hard Chrome Plating (HCP) at over 10,000psi. It has seen outstanding performance on piston rods that are particularly vulnerable to impact and wear, such as with Splash Zone cylinders.

Depths

In the depths of the ocean, there is less oxygen and so corrosion is not as much of an issue as it is at the surface. However, at depths far too deep for a diver to reach, there is a different challenge to overcome; accessing the equipment. Apex has experience of producing hydraulic equipment that can be operated remotely via Remote Operating Vehicles, utilising in-built hot stabs. This specialised design means that hydraulic cylinders can be placed on the sea bed months before they are needed, and accessed remotely when they are required.

Wind and Waves

On a remote oil rig or Floating Liquefied Natural Gas Rig, there is no protection from extreme weather conditions, meaning that equipment at the surface can receive regular battering from wind and waves. Therefore, equipment must be designed and manufactured to be extremely robust. Apex has years of experience in designing and manufacturing hydraulic cylinders to be incredibly resilient and yet lightweight. Apex utilise specially designed alloys, such as Inconel to ensure extremely strong cylinders that are resistant to corrosion. In addition, as described above, Apex have developed a market leading coating, Corex for piston rods, designed to be highly resistant to heavy impacts – not peeling or cracking as HCP might.

Apex are market leaders in developing and manufacturing robust hydraulics, designed to live up to the challenges provided by the offshore environment. For more information or to discuss your requirements, call Apex today on 01924 456788.

Some of Our Sector Experience

To find out more information about our experience of delivering successful projects across a range of operating environments, click on an image below…

More News Items

Read more from our news section. From time to time we will update the news section with industry insight, company updates and further products/services information…