The Recycling Industry is a fast-paced sector, moving quickly to develop more efficient machinery to respond to a nation recycling more than ever before. Innovation is key to success, with machines that can process more (and more quickly) being the aim for recycling tool manufacturers. One such leading manufacturer approached Apex with a request for a redevelopment of a top selling machine.

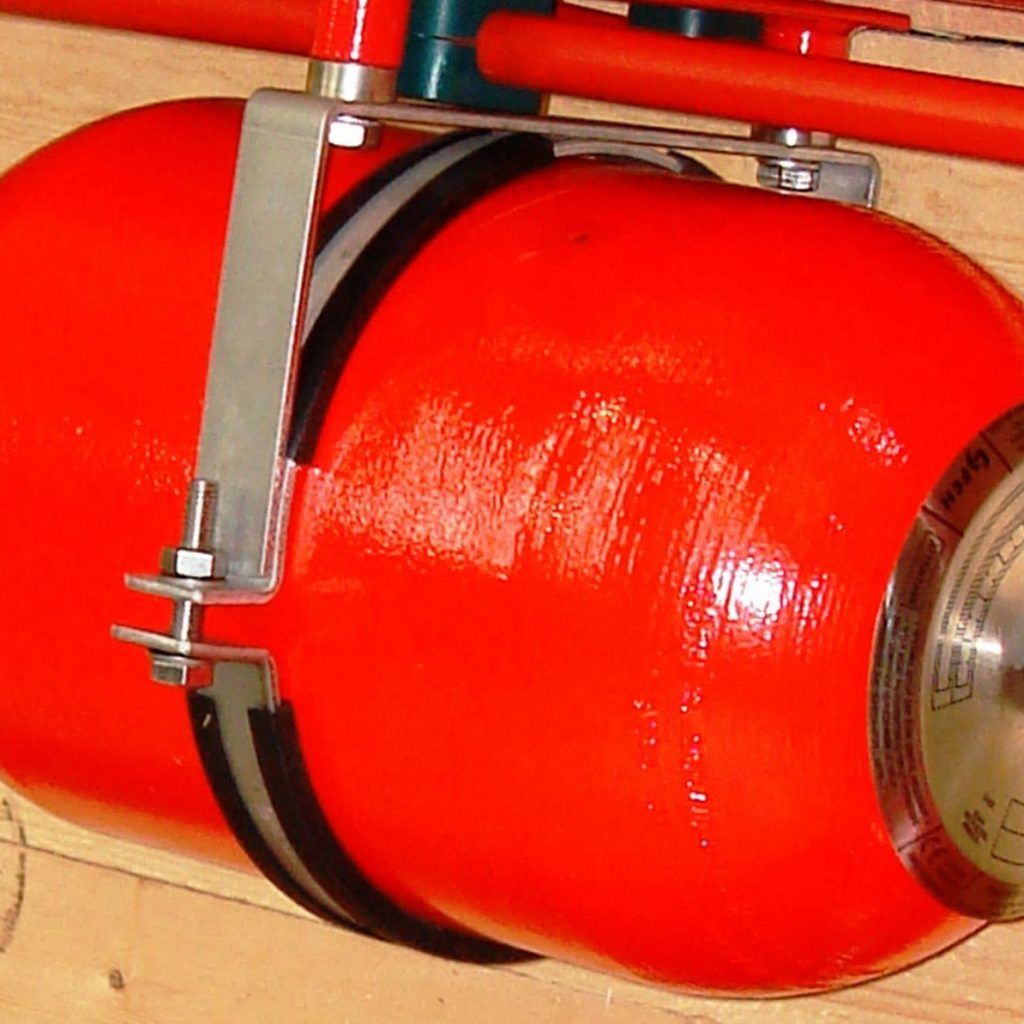

The machine is a baler; allowing large quantities of waste products, such as cardboard, plastic or clothing, to be condensed into relatively small bales ready to be stored in a compact form prior to further processing. The tool works by a hopper dropping quantities of waste onto a channel below. A hydraulic cylinder then squeezes it into a compression chamber at the end of the channel, baling it into compact cuboids. The hydraulic cylinder is double acting, retracting to allow the waste into the channel and advancing at pressure to repeat the process.

The Challenge

The machine had a number of challenges to its design.

- The machine works at speed and may be used continuously, so the design needed to be highly durable. A machine of this type may complete a full advance and retract in as little as 10 seconds. For this type of hydraulic cylinder, wear, tear and fatigue is a serious problem; with common causes of failure including damage to the seals, which allow contaminants into the hydraulic fluid, resulting in machinery break down. Seals were a particular challenge for this machine because the pressure throughout the stroke was varying; the initial cylinder rod advance was under very low pressure, but as it reached the compression chamber and forced the card into tight bales, the pressure became very high.

- The weld between the cylinder tube and base end was failing due to the repetitive cycling and constant use.

- When connecting the rod end, they experienced two difficulties; firstly, with the installation itself and secondly with producing a connection that could resist the repetitive advance and retraction forces.

- The client required a swift turnaround on the cylinders, eager to respond to their own customers with quick delivery once the machines were ordered.

Apex Solutions

Apex designers considered the above historic issues, before presenting the customer with a redesign that would address the challenges.

- They designed a specialised series of seals. The idea of the seal combinations was that the primary seal would work well under high pressure and the secondary seal would work well at low pressure. In conjunction with this, support rings were used that can absorb contamination from the oil to prevent these from reaching the seals. The seals were injection moulded to ensure that they had no seams or machine marks. These bespoke, superior seals are able to guarantee a longer lifespan for the cylinder, and therefore for the machinery itself.

- To resolve the issue of the failing weld, Apex redesigned the base. Full penetration welds were used to help reduce weld failures due to fatigue.

- Apex redesigned the rod end connection to utilise a high strength pusher pad and collet, to allow easy installation and to withstand the repetitive cycle action.

- Responding to the need for a quick turnaround on products, Apex Hydraulics now stock the cylinder parts in component form so that new orders can be completed within several days.

Results

The resulting cylinders are extremely durable, well designed cylinders that extend the life of the recycling tool. This results in a machine that can work more quickly, with less downtime and fewer costly repairs – giving the machines financial and environmental efficiency and aiding the customer in retaining their name for supplying top quality machines.

Related Products

The following products were utilised as part of this project. For more detailed information on these products, click on an image below…